*My posts may contain affiliate links, which means I may receive a small commission, at no cost to you, if you make a purchase through a link! Thank you for supporting my website!*

Last updated on February 28th, 2024 at 04:20 pm

Have you ever wondered what happens if you don’t sand between coats of polyurethane? I did too because I’m LAZY.

I mean, who has time to apply all of those coats of polyurethane AND sand between them?

So I ran some tests to show exactly what happens if you don’t sand between coats of polyurethane (and what happens if you do!) Here is what I found:

The texture of polyurethane is rougher if you do not sand between coats of polyurethane. However, the difference in finish is not visible to the naked eye. Each layer of polyurethane will still adhere together whether you sand between coats or not.

Now that I’ve fully tested my theory, I never have to worry about whether it will ruin my wood project by skipping sanding or not.

Below, I broke down my findings and how I ran the test, so you can determine whether sanding between coats of polyurethane is worth it for your wood project or not.

Let’s dive in!

Quick Navigation: What Happens When You Skip Sanding Between Coats Of Polyurethane

- How The Finish & Durability Turn Out When You Don’t Sand Between Coats Of Polyurethane

- Skipping Sanding Between Coats Of Polyurethane Results

- Sanding Between Coats Of Polyurethane Results

- Why Do Polyurethane Manufacturers Recommend Sanding Between Coats?

- What Happens If You Don’t Sand Between Coats of Polyurethane?

- Why You Might Not Want To Sand Between Coats

- How Many Coats of Polyurethane Should You Apply?

- How Long Should Polyurethane Dry Between Coats? (Sanding Or Not)

- How To Sand Polyurethane Between Coats

- Other FAQs About Applying Polyurethane

- Final Thoughts

How The Finish & Durability Turn Out When You Don’t Sand Between Coats Of Polyurethane

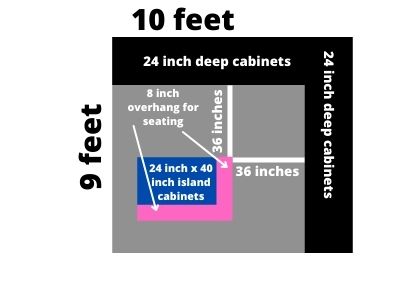

To test how much sanding between coats of polyurethane truly affects the finish and durability, I stained and taped off 7 sections on a piece of pinewood.

I tested the finish differences between no coats, 1 coat, 2 coats sanded between, 2 coats unsanded, 3 coats sanded between, 3 coats unsanded, and 3 coats sanded between with the final coat being sanded as well.

Here are the results I found:

| Coats Of Polyurethane | Finish | Durability |

|---|---|---|

| None | Rough | *Easily Scratched |

| 1 Coat | Rough | *Easily Scratched |

| 2 Coats, No Sanding | Slight Roughness | *Hard To Scratch |

| 2 Coats, Sanding | Smooth | *Hard To Scratch |

| 3 Coats, No Sanding | Slight Roughness | *No Scratches |

| 3 Coats, Sanding | Smooth | *No Scratches |

| 3 Coats, Sanding Including Final Coat | Rough | Scratched From Final Sanding |

Skipping Sanding Between Coats Of Polyurethane Results

There were obvious differences texture-wise between the areas of wood where I sanded between coats of polyurethane and the areas where I skipped the sanding.

When I ran my hand over the unsanded areas, I could feel tiny bumps and a slight roughness to the wood.

But to the naked eye, I could not tell a difference visually between the sanded and unsanded areas of wood.

That is excellent to know because if you are short on time, or if you are building a project that doesn’t matter if the texture isn’t perfectly smooth, then you can skip the sanding between coats.

We did not sand between coats when we applied polyurethane to our floating fireplace mantel. (If you’re curious as to how we built our mantel, you can find my tutorial here.)

Again visually, you cannot tell that we didn’t sand it.

And even when you run your hand over it, the texture is smooth enough that you wouldn’t notice a difference.

From the various wood projects where I skipped the part of the directions that told me to sand, I’ve never had the polyurethane peel off or have an issue adhering together.

The Secret To Getting A Perfect Polyurethane Finish Without Sanding

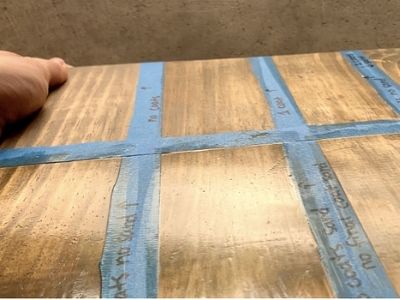

The main reason the polyurethane directions tell you to sand between coats is to buff out any drip marks or brushstrokes before you apply a second or third coat.

If you do have any obvious unevenness between coats, then you’ll want to sand. But my secret to avoiding brushstrokes in my polyurethane is to use a foam brush.

Yes, it’s that simple! I love to use these cheap, disposable foam brushes found at Amazon because they leave behind a smooth finish, and I can throw them away when I’m done with them.

(That’s always preferable with oil-based products because they’re a pain to clean haha.)

If you use that type of brush, then I wouldn’t worry about sanding between coats of polyurethane.

Also, oil-based polyurethane does a better job of leveling out brushstrokes than water-based (because it dries slower so it has more time to level out).

So that also aids in the argument to skip sanding between coats.

Sanding Between Coats Of Polyurethane Results

Now, there is a texture difference if you sand between coats of polyurethane.

Even with only two coats of polyurethane, the finish was amazingly smooth to the touch and had no imperfections when I sanded between coats.

And when the third coat was added, the wood project was smooth and durable. The exact type of finish I’d like to see on a tabletop that sees a lot of daily use.

But I find it hard to say you need to sand between coats of polyurethane on every project.

So my stance is this: If you have drip marks or brushstrokes, then a light sanding will help even out the finish and create a smooth project.

But if you use a foam brush and apply even, light layers of polyurethane, then it’s better to just save your time and skip the sanding between coats.

I’ve also used MinWax’s Water-Based Polycrylic found at Amazon and lightly sanded between coats using 600 grit sandpaper for this console table I built.

And I skipped the sanding between coats on Polycrylic for this small end table I built out of scrap wood.

The outcomes were the same as the oil-based polyurethane:

- Sanding between coats of water-based polyurethane is not required for adhesion

- Sanding between coats of water-based polyurethane does make the finish smoother

These are the products I used for both tables:

Why Do Polyurethane Manufacturers Recommend Sanding Between Coats?

Now that you’ve read what happened during my experiment, I’m sure you’re wondering, why do polyurethane manufacturers recommend sanding between coats if you don’t have to?

Most manufacturers have a timeframe listed on the can that states when it is recommended to sand between coats and when it is not necessary to sand between coats.

For most oil-based polyurethanes, it is recommended to:

- Not sand when the latest coat has dried between 4 and 12 hours or

- Sand lightly when the latest coat has dried for over 12 hours

For most water-based polyurethanes, it is recommended to:

- Not sand at all or

- Sand lightly when the latest coat has dried for over 2 hours

For most spar urethanes, it is recommended to:

- Not sand when the latest coat has dried between 8 and 12 hours or

- Sand lightly when the latest coat has dried for over 12 hours

Note: This does not include the final coat. You do not sand the final coat, you only buff it (more on this below).

This timeframe is listed on the can because if you sand too early, then the polyurethane can be too soft and becomes clumpy from sanding.

After 12 hours, polyurethane becomes hard enough to be scuff sanded.

Although, even though the manufacturer states it, you do not have to sand between coats after this 12-hour recommendation.

They are highly motivated for you to use more of their product, which sanding away part of the layers will ultimately force you to do.

Through my experiment results I showed above, sanding between coats of oil-based polyurethane is not required for adhesion, only for ultimate smoothness.

In fact, Popular Woodworking also says it’s a myth that you have to sand between coats for adhesion.

However, most professional woodworkers will still recommend you sand between coats to ensure that no dust or brush marks are left behind in the finish.

Personally, I decide which technique I want to use based on my project. If I have extra time, see some obvious imperfections, or just want a smoother finish in general, then I will sand between coats.

Otherwise, I will skip the sanding and save some time.

What Happens If You Don’t Sand Between Coats of Polyurethane?

The main problem that can happen if you don’t sand between coats of polyurethane is that dust particles, bubbles, or brush marks can show up in the polyurethane. Sometimes these problems are not visible until the final coat is dried. Sanding between coats helps remove any hidden unevenness during the application

Some woodworkers say that the polyurethane won’t adhere properly and eventually will peel if you do not sand between coats.

In my experience, I’ve never had an issue with polyurethane (oil- or water-based) peeling from lack of sanding between coats.

But if you are concerned about this possibility, then just lightly sand between coats. That way, there’s nothing to worry about.

Or you can run your own experiment on a scrap piece of wood before applying it to your real project to see if you like the sanded or unsanded finish better.

Why You Might Not Want To Sand Between Coats

The main problem that can happen if you DO sand between coats of polyurethane is that you can easily sand through the layers and require several more coats of polyurethane to be applied. To avoid this, use 220 grit working up to 600 grit sandpaper and apply very little pressure while hand sanding.

Some woodworkers even like to only sand between the second and third coats because it helps them avoid sanding too far down and messing up the stain or paint job.

When I have sanded between coats, I’ve lightly sanded with 220 grit between every coat (not just the second and third coats) and have had success with that.

Only sanding between the second and third coat can be a happy medium to save more time and still get a little bit smoother finish.

UPDATE: Since I originally wrote this post, I’ve now sanded a water-based polyurethane-coated console table with 600 grit sandpaper between coats and the finish did turn out smoother and thicker than my previous projects where I sanded using 220 grit.

It easily removed any drip marks I accidentally made during the application process without removing so much of the finish that it felt like I wasn’t gaining any layers.

Moving forward on my projects, if I want a much smoother finish, I plan on lightly sanding between coats with 600 grit sandpaper.

As with many things in the world, sanding or not sanding between coats is more of a personal preference than a truly hard and fast rule.

Now that we’ve been over the difference between sanding and not sanding polyurethane, you might be in the boat that sanding is worth it for your wood project.

That’s excellent! Now, let’s talk about how to sand between coats of polyurethane for ultimate success.

How Many Coats of Polyurethane Should You Apply?

Regardless of whether you are sanding or not between coats, you should apply 3 coats of polyurethane.

As my experiment showed above, the most durable finish I had was when I applied 3 full coats.

One coat of polyurethane is not enough to create a thick film over the wood, so it can easily be scratched with a fingernail.

Two coats of polyurethane are better and are typically the minimum coat recommendation by most manufacturers.

Again, if your project is not getting touched or used that frequently, then you can likely get away with only 2 coats.

But if you are applying the topcoat to furniture or hardwood floors, then you will want 3 coats for maximum durability.

How Long Should Polyurethane Dry Between Coats? (Sanding Or Not)

| Type Of Urethane | How Long To Let Polyurethane Dry Between Coats Without Sanding | How Long To Let Polyurethane Dry Between Coats With Sanding |

|---|---|---|

| Oil-Based Polyurethane | Between 4 and 12 hours | Over 12 hours |

| Water-Based Polyurethane | Between 2 and 12 hours | Over 12 hours |

| Spar Urethane | Between 8 and 12 hours | Over 12 hours |

The longer you wait before applying the next coat of polyurethane, the more time the previous coat has to cure.

Until the previous coat has fully cured (which can take over a month for some types of poly), any additional coats re-soften the coat before it (especially oil- and alcohol-based topcoats).

This hardening helps prevent the wood grain from constantly being raised and needing to be resanded.

However, it’s unreasonable to wait for days, weeks, or months to apply a second or third coat to your wood project. So just take this into consideration when you are sanding.

You will not be able to get every single imperfection and dust nib 100% removed, so sand lightly between coats or don’t sand at all and move on.

How To Sand Polyurethane Between Coats

Here is a great video demonstrating how to sand between coats of polyurethane for a perfectly smooth finish.

He’s got a great piece of advice in there for removing any remaining imperfections from the final coat of polyurethane.

It’s called buffing the polyurethane, and he uses a brown paper bag to give a final wipe down and smooth out any remaining dust nibs from the final dried coat.

Other FAQs About Applying Polyurethane

Here are some other frequently asked questions about applying polyurethane to help you get the perfect finish on your wood projects!

What Grit Sandpaper Should You Use To Sand Polyurethane?

Use 220 grit sandpaper or higher to sand polyurethane and progressively increase the grit as you add more layers (320, 600, and 1500 for the final coat). This will remove imperfections in the polyurethane while leaving a thick topcoat.

I’ve always wondered if you could use a mechanical sander to sand between coats of polyurethane or if you had to hand sand between coats.

(That would be an excellent way to save time AND get the perfectly smooth finish!)

So I ran a test to see what would happen! You can find out if you can use an orbital/palm sander between coats of polyurethane from my article here.

Do You Sand The Final Coat Of Polyurethane?

During this experiment, I also tested whether you should sand the final coat of polyurethane or not. The answer is pretty clear:

It is recommended to avoid sanding the final coat of polyurethane. Sanding the final coat scratches the surface and leaves behind a cloudy appearance. Only sand between coats of polyurethane to achieve a smooth finish and skip sanding the final coat.

To see the full experiment results and the testing process, check out my article here.

Instead of sanding the final coat, you can buff the final coat with a brown paper bag to remove any remaining dust nibs and help the final coat shine.

Is It Better To Brush Or Roll Polyurethane?

It is better to brush polyurethane on with a fine foam brush. Rolling polyurethane creates bubbles in the finish that will need to be sanded away before applying another coat. Brushing the polyurethane with a foam brush minimizes brush marks and does not create bubbles in the finish.

What Do You Do With A Polyurethane Brush Between Coats?

To save a polyurethane brush between coats, pour mineral spirits (for oil-based) or water (for water-based) in a cup and dunk the brush into it to wash out the polyurethane. Squeeze out any excess mineral spirits/water from the brush using a paper towel and let the brush air dry until it’s time to apply the next coat.

Can You Apply Polyurethane Over Old Polyurethane?

Old polyurethane should be sanded down or removed before applying a fresh coat of polyurethane. If the old polyurethane is in poor condition, then it needs to be fully removed with 100 grit sandpaper. Otherwise, the old polyurethane only needs the top layer scuffed with 120-220 grit sandpaper.

Final Thoughts On What Happens If You Don’t Sand Between Coats Of Polyurethane

There you have it!

It is safe to say you can apply several coats of polyurethane without sanding between them and not even bat an eye.

Your wood project will still turn out beautifully. So save the time and the extra money on sandpaper, and apply polyurethane with a foam brush to get the finish you want!

And for special occasions, you can sand between coats of polyurethane with 220-600 grit sandpaper to get the smoothest finish possible.

Catch you in my next post!

By Christine

Christine is a blogger and DIYer who tackles home renovation and decorating projects alongside her husband, Adam, for their personal residence and rental properties. Although she successfully tackles large renovation projects to avoid expensive contractor fees and bring her vision to life now, her path to success was not easy.

Go here to read her story, “From a Clueless First-Time Homebuyer To A Confident DIYer Creating Her Dream Home One Project At A Time“.

Popular Posts

DIY With Christine is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com.